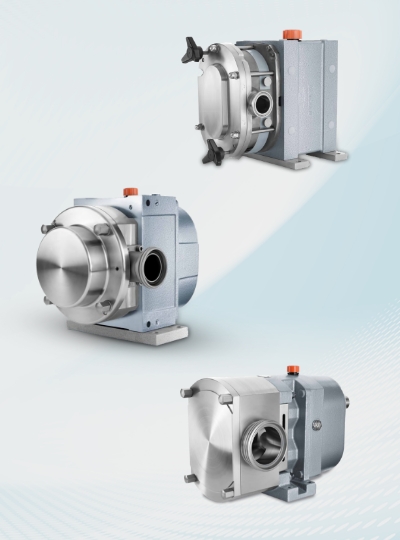

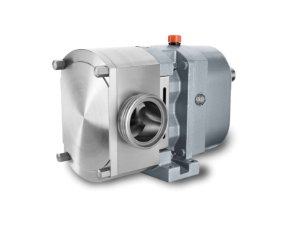

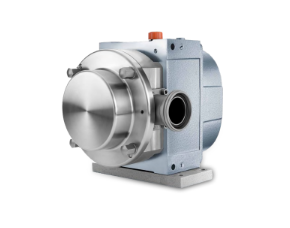

Rotary Lobe Pumps

Customisable features for tailored pumping performance

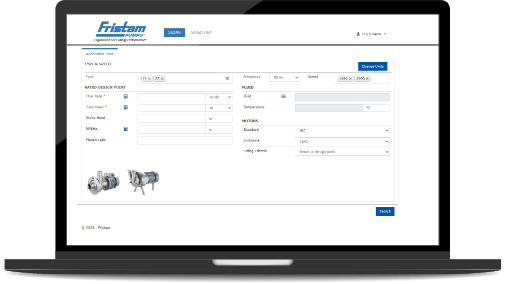

Fristam’s Rotary Lobe Pumps offer high efficiency and manage exceptionally high-viscosity substances, up to 1,000,000 mPa.s (FKL and FK Series). Utilising contra-rotating, non-contacting rotary lobes and modern lobe design, they minimise product damage and ensure extremely low backflows, suitable for discharge pressures up to 12 bar. These pumps, crafted from robust stainless steel alloys, guarantee reliability and longevity, all while meeting the highest hygiene standards, with their design facilitating complete Clean-in-Place (CIP) and Sterilisation-in-Place (SIP). With diverse models, ease of maintenance, and customisable features, these pumps offer an optimum solution for various applications, ensuring maximum productivity with minimal downtime. Further expanding on the product range are Fristam FKL and FK series. The FKL series, with 10 different sizes, handles discharge pressures up to 35 bar and flow rates up to 120 m3/h, ideal for high-pressure, high-flow applications. Likewise, in 5 sizes, the FK series manages discharge pressures up to 20 bar and flow rates up to 25 m3/h, perfect for moderate demands. These series form a comprehensive solution set for diverse industrial pumping needs.

FAQs

1. What is a rotary lobe pump, and how does it operate?

A rotary lobe pump is a positive displacement pump, they are designed for outstanding suction performance and high flow rates with highly viscous products. Its clever design along with two non-contacting small lobes minimizing wear and contamination risk, also make it enable for easy maintenance, perfect durability, gentle product handling, low pulsation, and versatility, it severs in diverse industrial applications including food processing, pharmaceutical and chemical manufacturing.

2. What are the advantages of high-performance rotary lobe pumps?

The High-performance rotary lobe pumps offer diverse advantages to make them suitable for demanding industrial applications such as Gentle fluid handling with minimum shear & Pulsation, delivering constant and highly efficient performance for high-viscous or abrasive fluids, self-priming capability and handling fluids with entrained air or gases, constructing by using stainless steel the material makes it corrosion resistant, modular design allows for easy maintenance, offers CIP (Clean-in-place) and SIP (Sterilize in place) capabilities, Sanitary design as per regular compliance.

3. Are rotary lobe pumps energy-efficient?

Yes, the rotary lobe pumps are more convenient in energy efficient than traditional pumps and the energy consumption depends on diverse industrial applications and type of fluids, get leakage-free operations due to the pump's sturdy internal slip and tight clearance. Pumps are self-primed which lowers energy consumption while operating. The specific robust design makes pumps more longevity, easy to handle with minimal downtime and lower maintenance costs.

4. What is the lifespan of Fristam's rotary lobe pumps?

As per the demand of industrial applications Fristam's rotary lobe pumps last 10-20 years whereas multiple factors are considerable such as building material, application, working condition, and timely maintenance.

5. How much flow can Fristam's rotary lobe pumps handle?

The basic parameters are needed in handling a flow by Fristam rotary lobe pumps which are viscosity, flow rate, pressure, and material strength to ensure the pump's lifespan and its high performance.