Industrial processes are typically faced with a critical problem: finding a pump that can balance efficiency, versatility, and hygiene in handling a wide range of viscosities. Traditional pumps like gear pumps are not up to the task without compromising performance or increasing maintenance costs.

For the food, dairy, beverages & brewing, chemical and personal care industries, the stakes are higher. Products need to be handled very gently to keep the quality intact. On the other hand, hygiene standards are very strict, which makes it necessary to have pumps that can easily switch between production mode and cleaning mode. Twin screw pumps come in here to help solve modern pumping challenges.

The Challenges of Traditional Pumping Systems

- Limited Versatility: Most pumps are made to operate with a specific viscosity or for a particular application, thus necessitating several systems for production and cleaning

- High Maintenance Costs: Frequent breakdowns or wear and tear resulting from inefficiency in handling viscous or abrasive products

- Hygiene Concerns: Conventional pumps do not have the sophisticated cleaning ability required for industries that have stringent sanitary demands

These challenges not only increase the operational costs but also hinder productivity, making it essential to adopt innovative solutions like twin screw pumps.

What Are Twin Screw Pumps?

Twin screw pumps are positive displacement pumps, capable of handling wide ranges of viscosities. These high-efficiency pumps are equipped with two intermeshing screws that rotate to transfer fluid and ensure smooth flow. Their versatility in performing production and cleaning makes them a necessary tool for various industries.

Applications of Twin Screw Pumps

These pumps are versatile and useful across various industries. Some of the twin screw pump applications are below:

- Food Processing: Tackle highly viscous products like sauces and pastes with efficiency

- Beverages: The delicate transfer of juice, milk, and other sensitive liquids

- Dairy: Managing high viscosity and CIP processes in one flow

Why Twin Screw Pumps Are the Solution

Twin screw pumps have been the answer to most industrial pumping challenges. A product of innovative engineering that is versatile in tackling viscosities while at the same time efficient, hygienic, and durable.

1. No Match in Versatility

Twin screw pumps can handle anything from highly viscous products like creams or syrups to thin cleaning agents. Therefore, cleaning pumps are not necessary. Additionally, by combining double-screw technology with high quality standards make it for a wide range of applications and offer maximum flexibility.

2. High-Pressure Handling Efficiency

They can operate at significant differential pressures without overheating or degrading their performance characteristics. The Fristam FDS series is engineered to work well in the most extreme conditions. Handling even very low NPSH conditions.

3. Gentle and Hygienic Handling

For industries such as dairy and food processing, maintaining product integrity is essential. Twin screw pumps ensure gentle handling with minimal shear, thus preserving the quality of sensitive products. Their Clean-in-Place (CIP) and Sterilization-in-Place (SIP) capabilities also meet the highest hygiene standards. Also, with set-up of contact-free feed screws in FDS that avoid any contamination of the product.

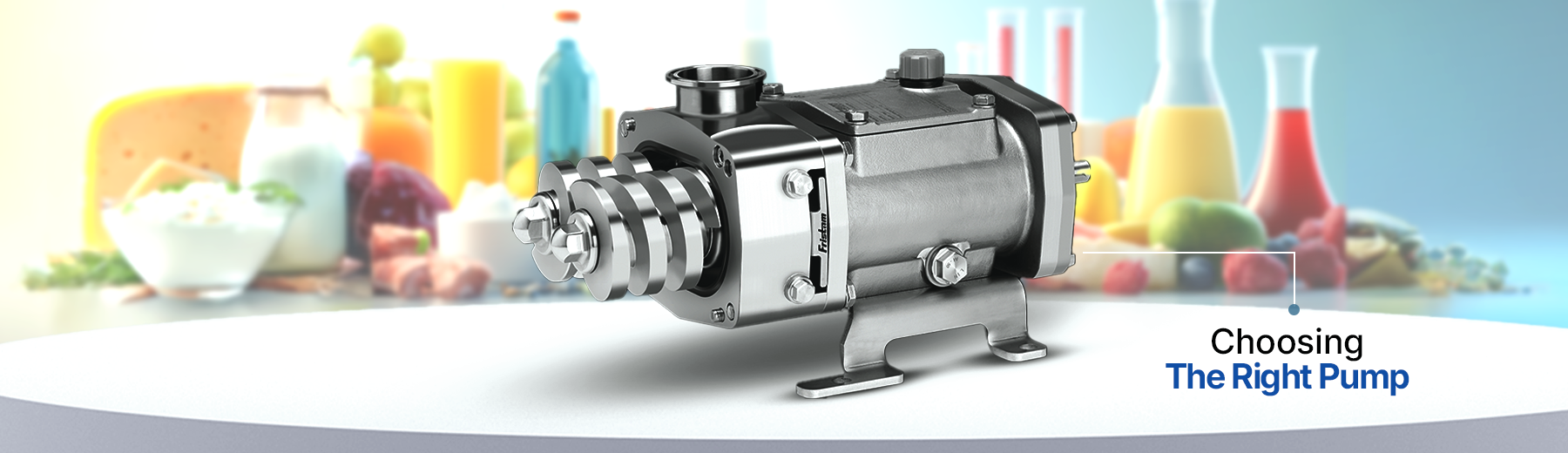

Fristam Twin Screw Pumps: A Better Alternative

Fristam has changed the face of this technology with its FDS series, setting a new benchmark for performance and reliability.

1. Advanced Design Features

- Mechanical Seals: Filled seals minimize leakage risks and make maintenance easier

- Three-Piece Casing: Facilitates easy accessibility and customization, which assures flexibility to different system pumps

- Special Design Bearings: With compact size and special bearings designed the Fristam FDS pumps can be mounted horizontally as well as vertically.

- Rigid Shaft: With reinforced shaft design, to get smooth run along with lower operating temperatures also under elevated pressure, it expands FDS’s longevity significantly.

2. Heavy Construction for Longer Life

With a smart gearbox design, Fristam twin screw pumps operate smoothly even under extreme conditions, reducing wear and extending lifespan.

Conclusion

The right pump is crucial for operational success, and twin screw pumps offer unparalleled advantages. Fristam's innovative solutions, like the FDS series, deliver high performance, hygiene, and flexibility, making them the ideal choice for your industrial needs.

Explore Fristam's twin screw pump range and experience the difference in efficiency and reliability. Call us today to find out more!

FAQs:

1) What is a screw pump used for?

A screw pump is used to transfer fluids with varying viscosities, ensuring smooth, continuous flow in industries like food, beverage, and chemical processing.

2. What is the difference between single screw and twin screw pumps?

Single screw pumps handle low to medium viscosities, while twin screw pumps manage a wider range, offering higher efficiency, gentle handling, and dual-purpose production and cleaning capabilities.