5 Proven Tips – How do Fristam’s products help to Overcome Challenges in Dairy Processing?

January 6, 2025

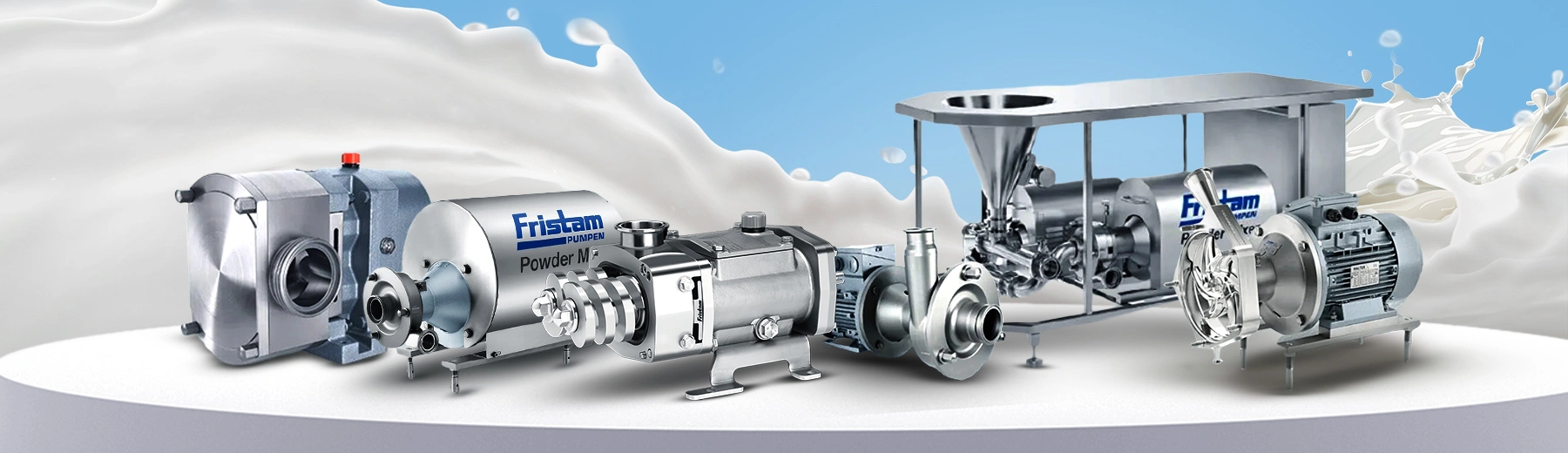

Dairy processing in India presents a unique set of challenges, from ensuring product quality to maintaining hygiene standards. The use of advanced dairy processing equipment can make a significant difference in achieving consistent, high-quality products. In this blog, we’ll explore five proven tips that can help overcome common challenges in dairy processing, with a focus on the equipment that makes these solutions possible.

1. Use the Right Dairy Processing Equipment for Efficient Milk Handling

Dairy processing involves one of the major problems that arise during handling: ensuring the effective handling of milk while its quality is retained. The most effective method for achieving this is by applying specialized dairy processing equipment, such as the FP Centrifugal Pump.

Fristam's FP centrifugal pump delivers maximum efficiency with minimal product damage by gentle milk handling. With a flow rate of up to 550 m³/h and with viscosities up to 800 mPa.s, it is ideal for high-volume dairy operations. Its design is robust and energy efficient, making it a reliable choice for any dairy processing plant.

2. Maintain Hygiene with Sanitary Pumps and Equipment

Hygiene is of the utmost importance in dairy processing since milk is a highly perishable product. Sanitary pumps are to be used only if they meet stringent hygienic standards.

Fristam's FL/FL3 positive displacement pumps are designed for hygienic applications. The helical rotor design of the FL3 model ensures gentle product handling with minimal pulsation. This is essential in milk and dairy products.

The FL3 can execute Clean-in-Place (CIP) and Sterilisation-in-Place (SIP) and thus requires minimal support of secondary cleaning equipment and time is saved.

The low-maintenance designed series of FL has gained an edge as they promise durability, long life, and minimal downtimes for dairy plants. Compact and easily cleaned, these pumps fit best in high-pressure applications involving less flow of materials; they thus become highly versatile in the context of dairy processing.

3. Ensure Consistent Mixing with Powder Mixers

In dairy processing, it's more than just handling liquid milk; many dairy products call for the precise mixing of powders and liquids. With powder mixers such as our PM and PMV powder mixers, dry and wet ingredients will be blended together in a seamless way with consistency and high-quality products guaranteed to come out. Whether you're creating powdered milk, flavored milk, or other dairy-based products, these mixers are essential for smooth homogenous texture.

The PM powder mixer draws powder directly into the fluid stream using centrifugal pumps to ensure complete blending. The PMV powder mixer has an FL3 positive displacement pump with a shear pump to get a perfect mix. These mixers are equipped for CIP and SIP processes, which make them hygienic and efficient in mixing.

4. Minimize Product Damage with Twin screw pumps

Milk and other dairy products are very delicate, and any damage done during processing can cause quality loss. To solve this problem, twin screw pumps must be used that would handle the product gently. Fristam's FDS and FDS-TSG screw pumps series are ideal for thick products such as yogurt or cream, which require gentle treatment.

These pumps are designed by revolutionising twin screw technology, ideal for peerless smooth operation, temperature stability and seamless maintenance. It handles low to high viscous products and saves the need of separate cleaning pumps. It offers gentle fluid without damaging the physical property of products.

5. Optimize Operational Efficiency with Multi-Function Pumps

In dairy processing, the cost of operation must be kept at the lowest level without sacrificing performance. Multi-function pumps such as the FL/FL3 positive displacement pumps can handle both product and CIP fluids. This eliminates the need for separate pumps for cleaning and product transfer. It saves space and also reduces the complexity of the system and helps make operations more efficient.

The FL3 pump is a high-pressure and flow-rates handling pump that may be applied in many processes in dairy. It is adapted to deal with both low and high viscosities, hence can be applicable in any dairy product whether milk, cream, cheese, or others.

Why Choose Fristam for Your Dairy Processing Needs?

The right equipment is of paramount importance in dairy processing to ensure product quality, efficiency, and hygiene. Fristam's range of dairy processing equipment offers solutions to overcome common challenges for dairy processors.

Fristam makes sure that the dairy product is processed with the utmost care, as its equipment maintains a focus on gentle handling, hygiene, and efficiency. That’s why you can easily handle milk, mix powders, or transfer your high-viscosity products; Fristam provides you with the tools you need in order to succeed in today's competitive dairy industry.

Visit our website and explore our range of products tailored to meet the specific needs of the dairy industry.

FAQs:

1) What equipment is used in dairy production?

Equipment used in dairy production consists of a series of devices such as centrifugal pumps, positive displacement pumps, powder mixers, pasteurizers, separators, and homogenizers for effective and safe handling in its processing.

2) Which valve is used in the dairy industry?

The dairy industry commonly uses sanitary valves, such as butterfly valves, diaphragm valves, and check valves, designed for hygienic applications and CIP/SIP processes.